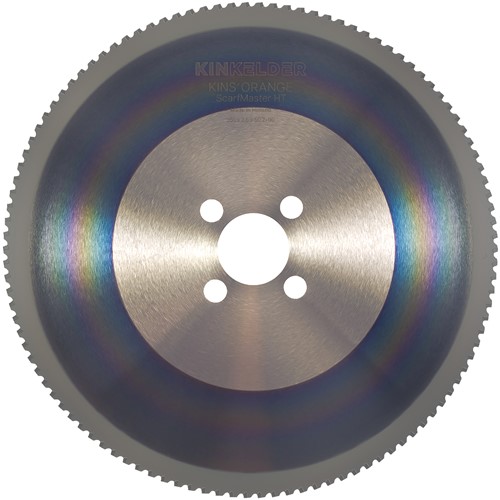

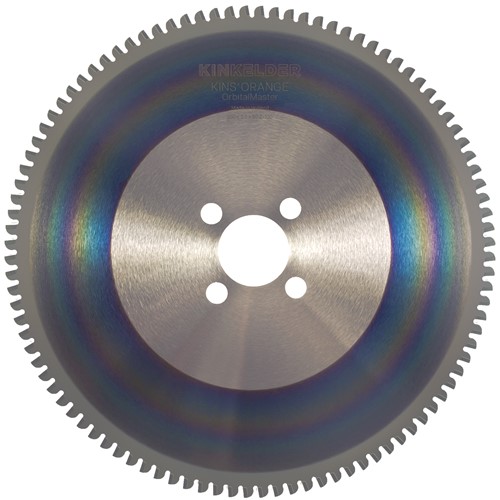

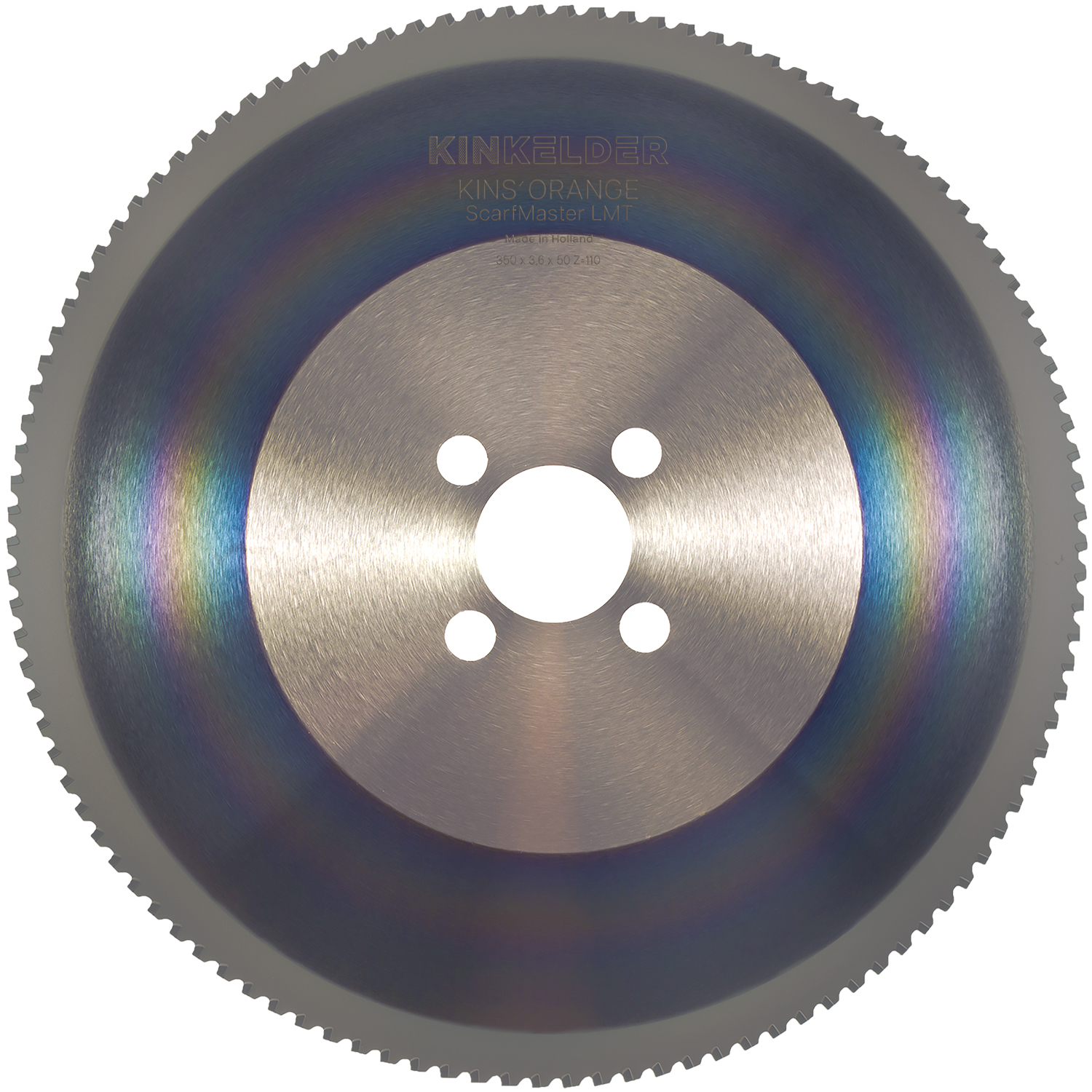

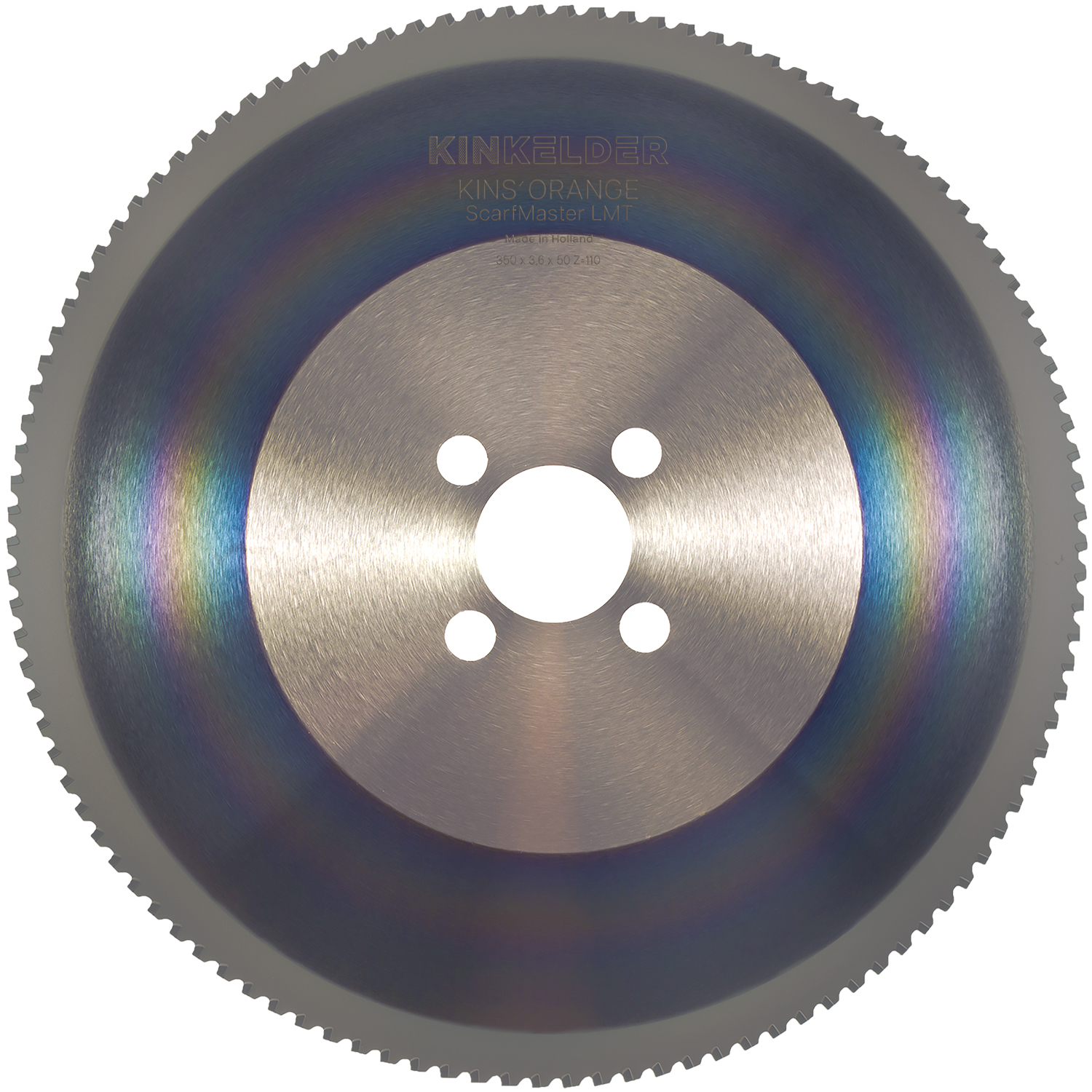

KINS' ORANGE ScarfMaster LMT

Single and Twin cut-off with inside scarf

Engineered for tube mills with flying cut-off applications handling the detached heavy weld bead inside the tube, the KINS' ORANGE ScarfMaster LMT saw blade delivers precision and durability. Its distinctive tooth geometry and highly shock-resistant carbide tips ensure excellence in cutting performance

-

Low/Med. Tensile

-

High Tensile

-

Scarf

-

Blade Life

Explore the possibilities within our wide range to optimize your sawing process

By exploring our sawing blades you can discover new ways to enhance efficiency, precision, and TCO of your sawing processes.