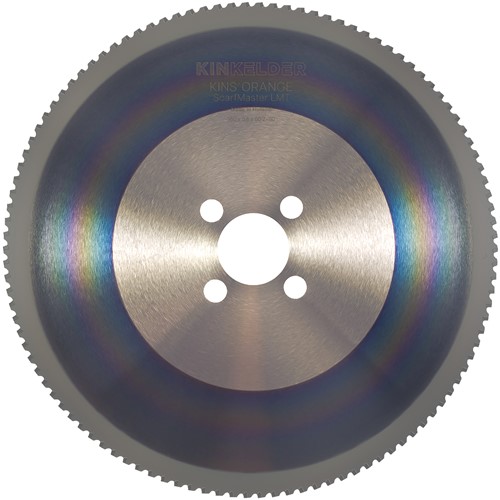

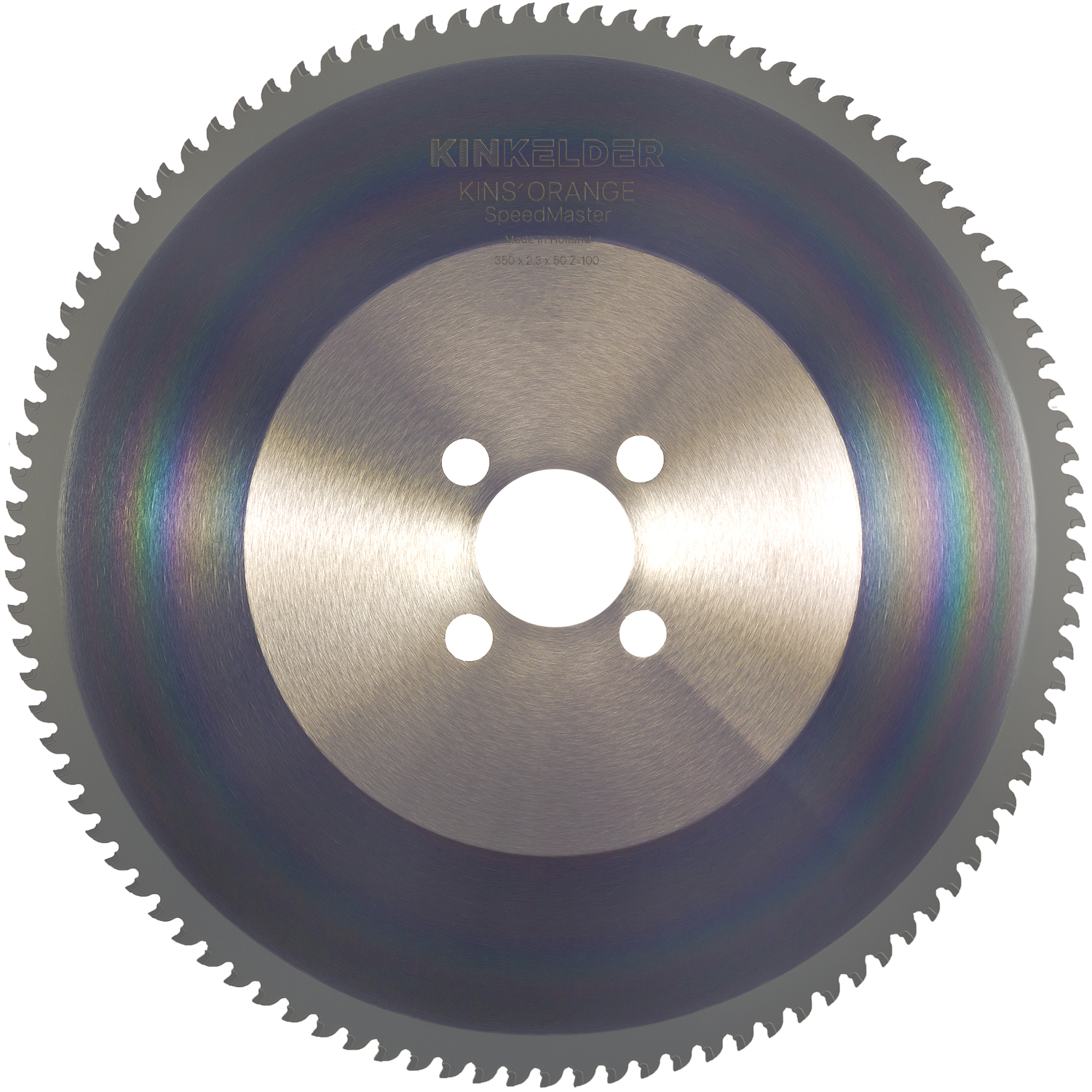

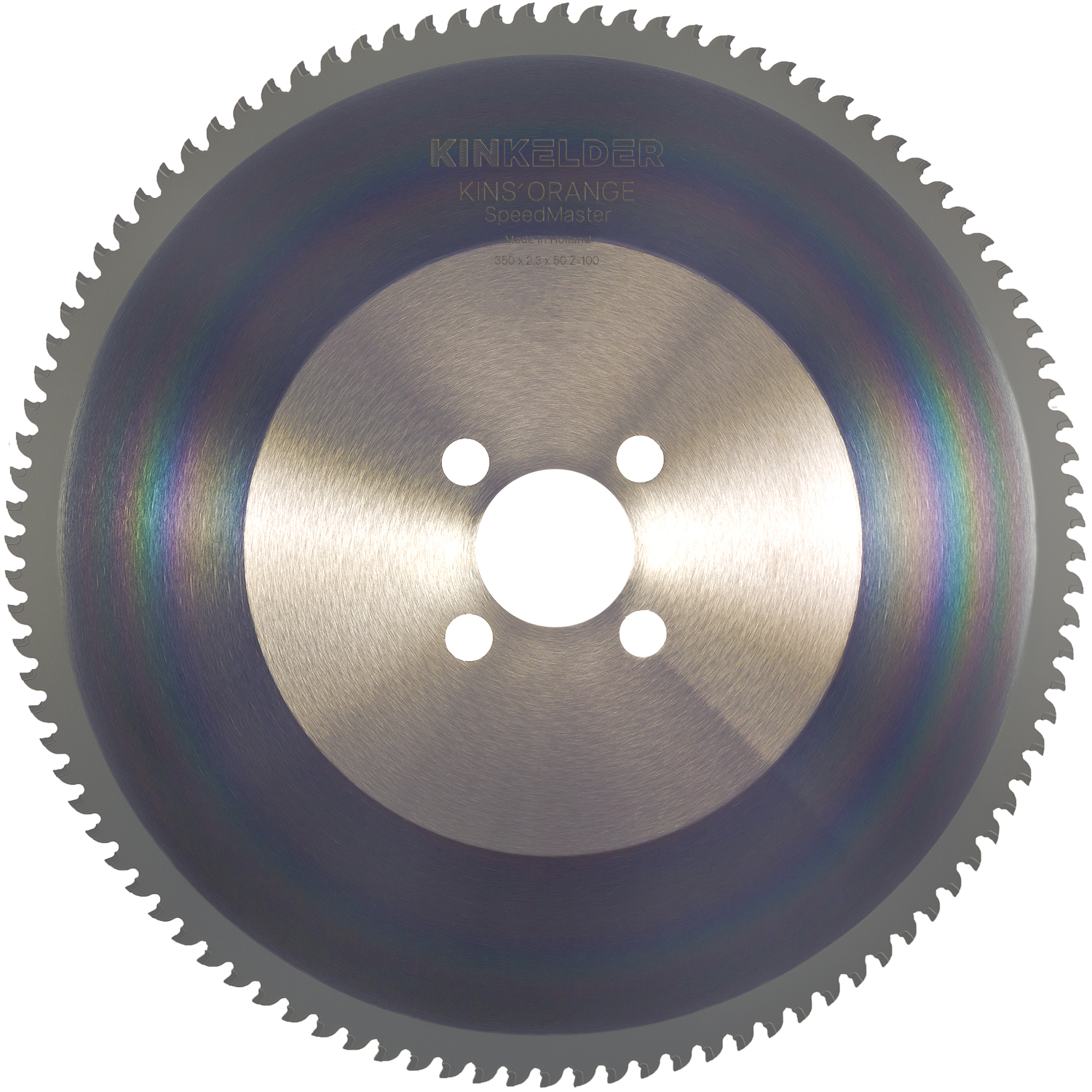

KINS' ORANGE SpeedMaster

Single and Twin cut-off without inside scarf

Elevate your tube mill process with the KINS’ ORANGE SpeedMaster saw blade. Precision-crafted for exceptional performance on blade life and cutting speed for flying cut-off applications in tube mills. Improve your productivity with long blade life, less downtime, and fast cutting.

This saw blade is designed for single cut or twin cut-off tube mills. For single tube processes where the inside scarf is removed, a KINS’ ORANGE ScarfMaster saw blade is recommended.

Our applications engineers are happy to help you choose the right blade, set the machine, and conduct the first trials on location.

-

Carbon Steel

-

Stainless Steel

-

Scarf

-

Blade Life

-

Tube

-

Thin tube/profile

Explore the possibilities within our wide range to optimize your sawing process

By exploring our sawing blades you can discover new ways to enhance efficiency, precision, and TCO of your sawing processes.