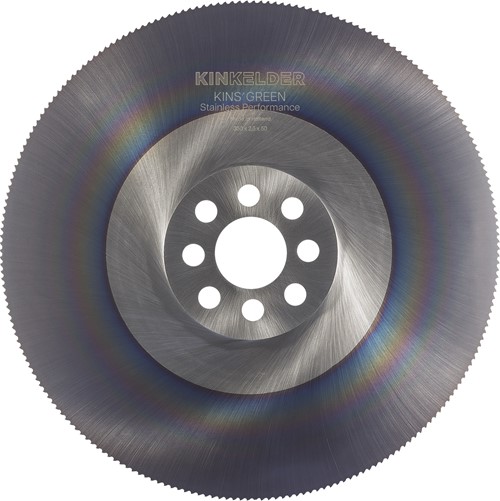

KINS' GREEN Stainless Stabilizer

Crafted to cut thin-walled stainless steel tubes and profiles

The KINS' GREEN Stainless Stabilizer saw blade is equipped with a specialized, thin PVD coating that offers low friction and temperature resistance. Along with a thinned cutting area, these saw blades demonstrate exceptional performance in demanding applications. They guarantee fast and efficient cutting of thin-walled stainless products, minimizing vibration, reducing burrs, diminishing the risk of tube-end deformation, and maintaining high temperature resistance. In challenging cutting conditions, this saw blade ensures optimal performance.

-

Stainless Steel

-

Cutting Speed

-

Blade Life

-

Tube

-

Thin Tube

Explore the possibilities within our wide range to optimize your sawing process

By exploring our sawing blades you can discover new ways to enhance efficiency, precision, and TCO of your sawing processes.