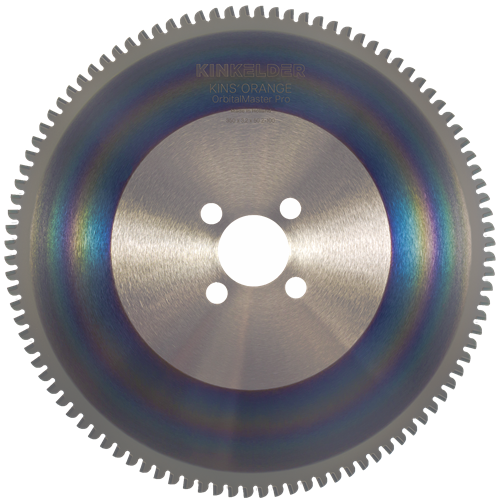

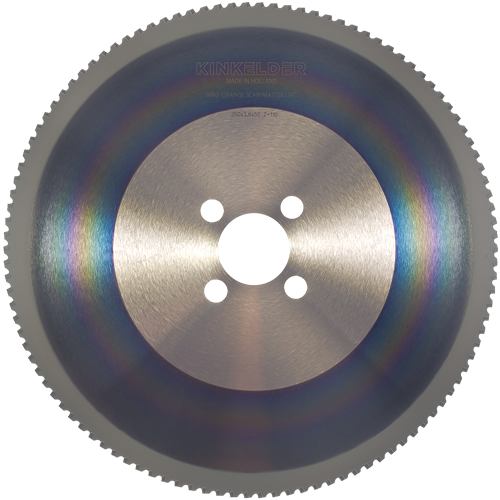

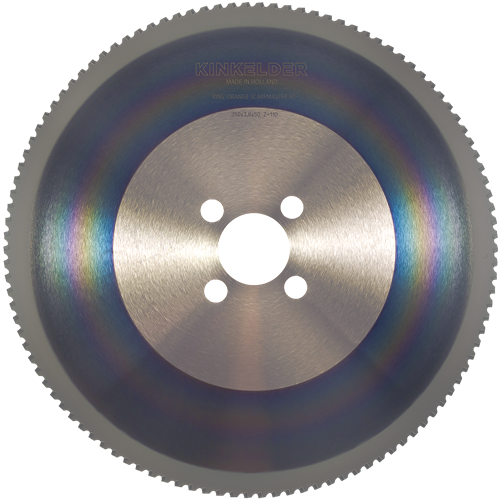

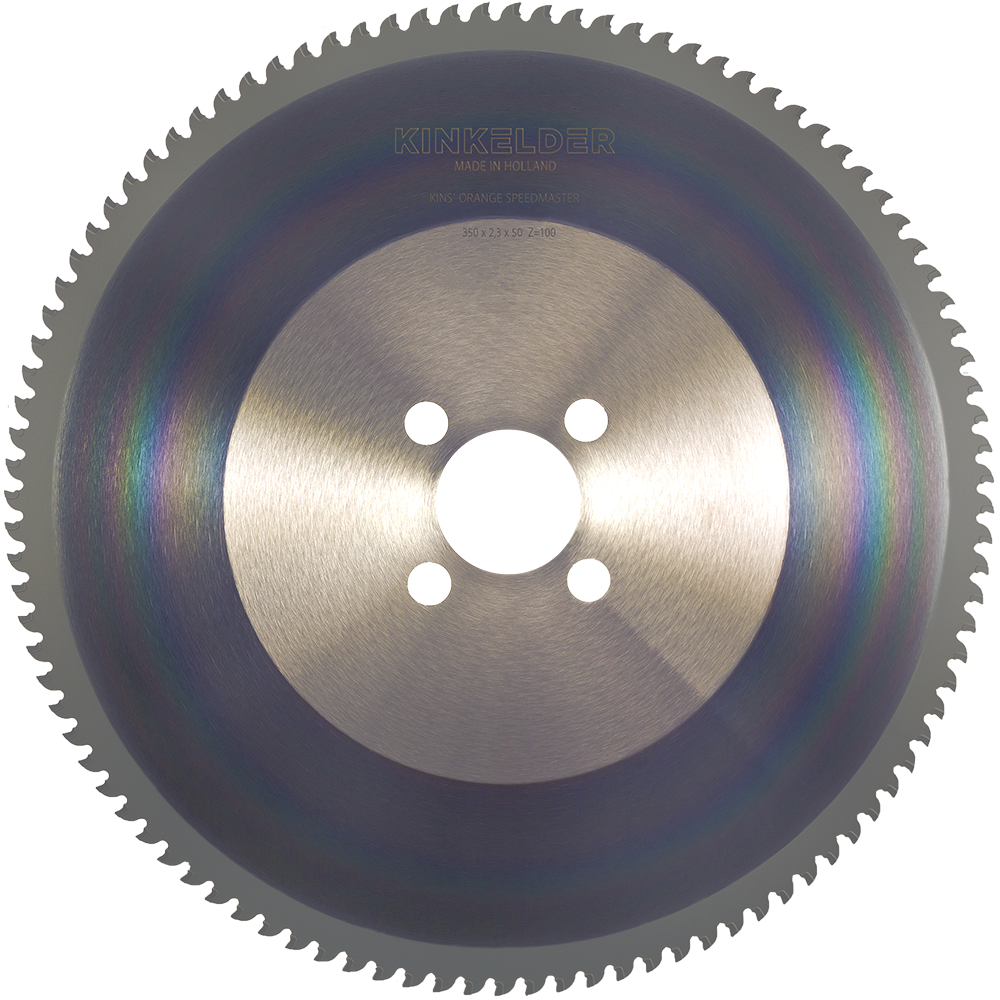

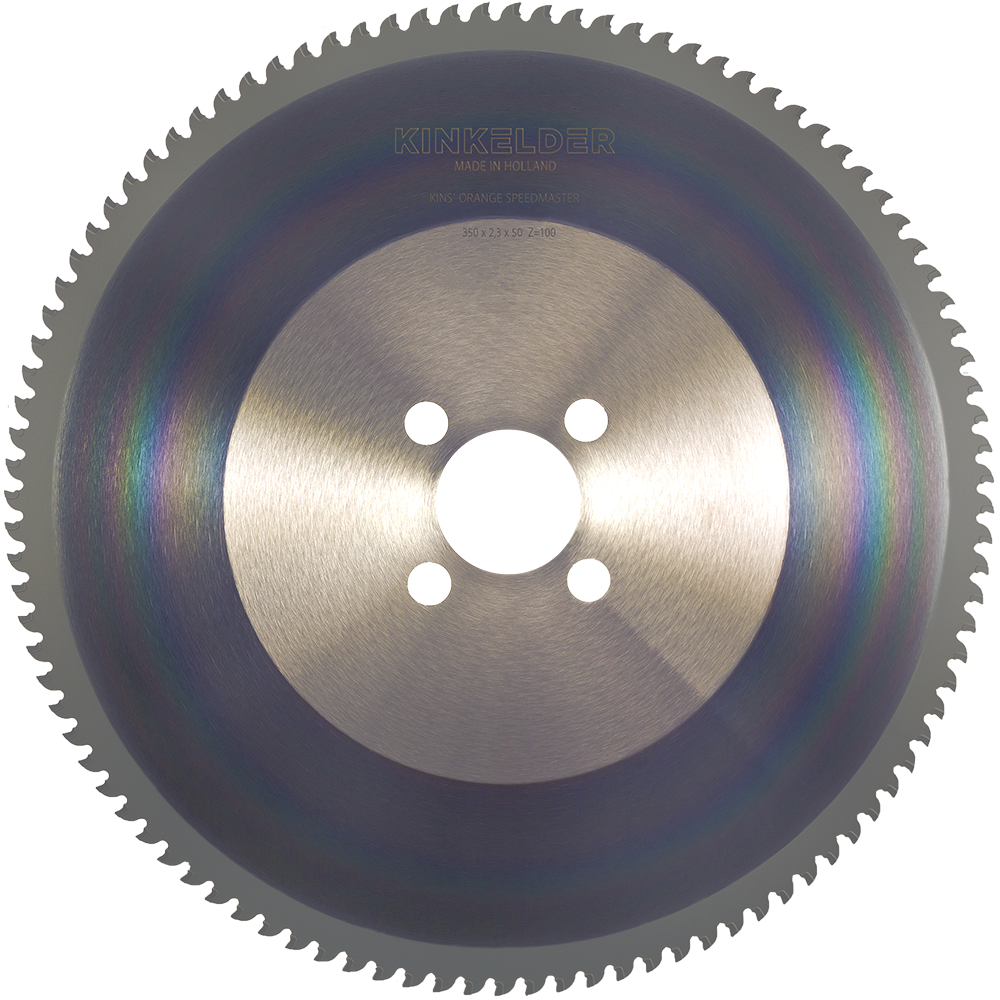

KINS' ORANGE SpeedMaster

Single and Twin cut-off without inside scarf

Elevate your tube mill process with the KINS’ ORANGE SpeedMaster saw blade. Precision-crafted for exceptional performance on blade life and cutting speed for flying cut-off applications in tube mills. Improve your productivity with long blade life, less downtime, and fast cutting.

This saw blade is designed for single cut or twin cut-off tube mills. For single tube processes where the inside scarf is removed, a KINS’ ORANGE ScarfMaster saw blade is recommended.

Our applications engineers are happy to help you choose the right blade, set the machine, and conduct the first trials on location.

-

Carbon Steel

-

Stainless Steel

-

Scarf

-

Blade Life

-

Thin Tube/Profile