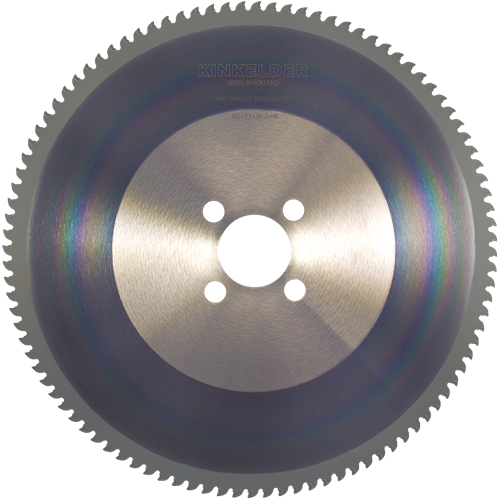

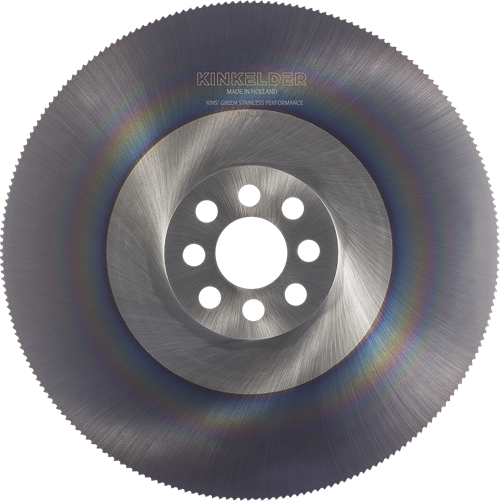

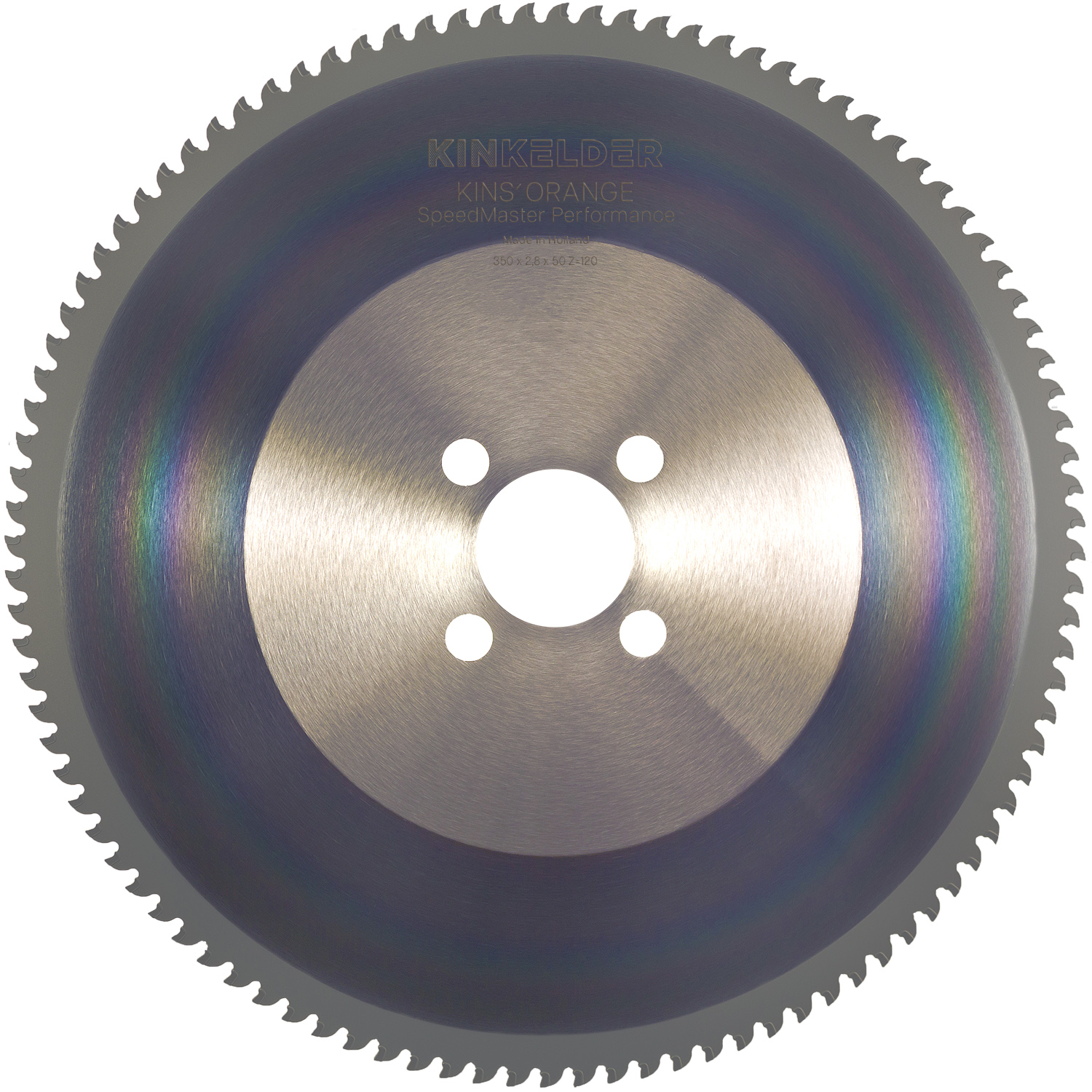

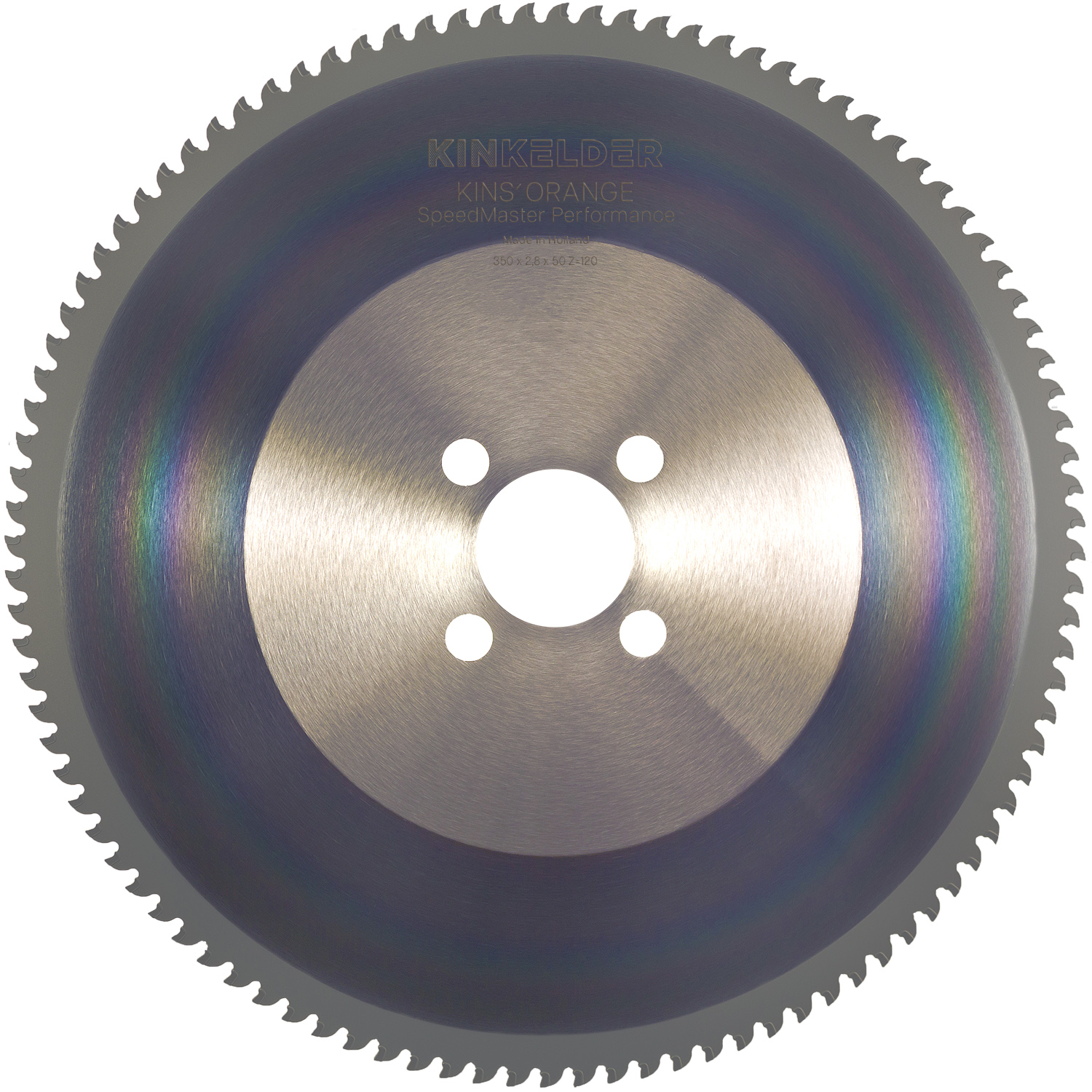

KINS' ORANGE SpeedMaster Performance

Single and Twin cut-off for thin wall profiles and tubes

Enhance your tube mill operations with the KINS’ ORANGE SpeedMaster Performance saw blades. Designed for superior performance in flying cut-off applications, it delivers shortest cut-times on carbon steel rectangular or square hollow sections and thin-wall tubes. Applicable on medium and high tensile strengths steels for both single and twin flying cut-off machines.

-

Low tensile

-

Medium tensile

-

High tensile

-

Cutting speed

-

Cutting time

-

Tube

-

Thin tube

-

Profile