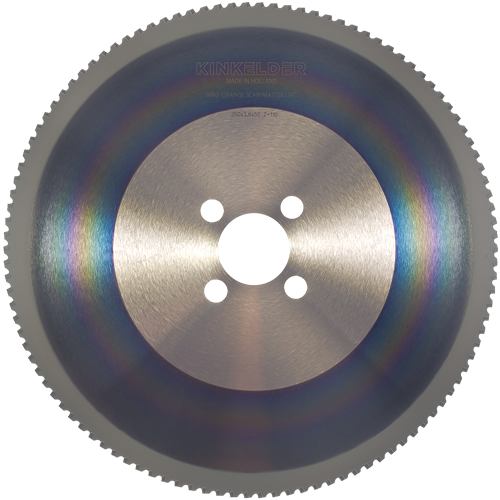

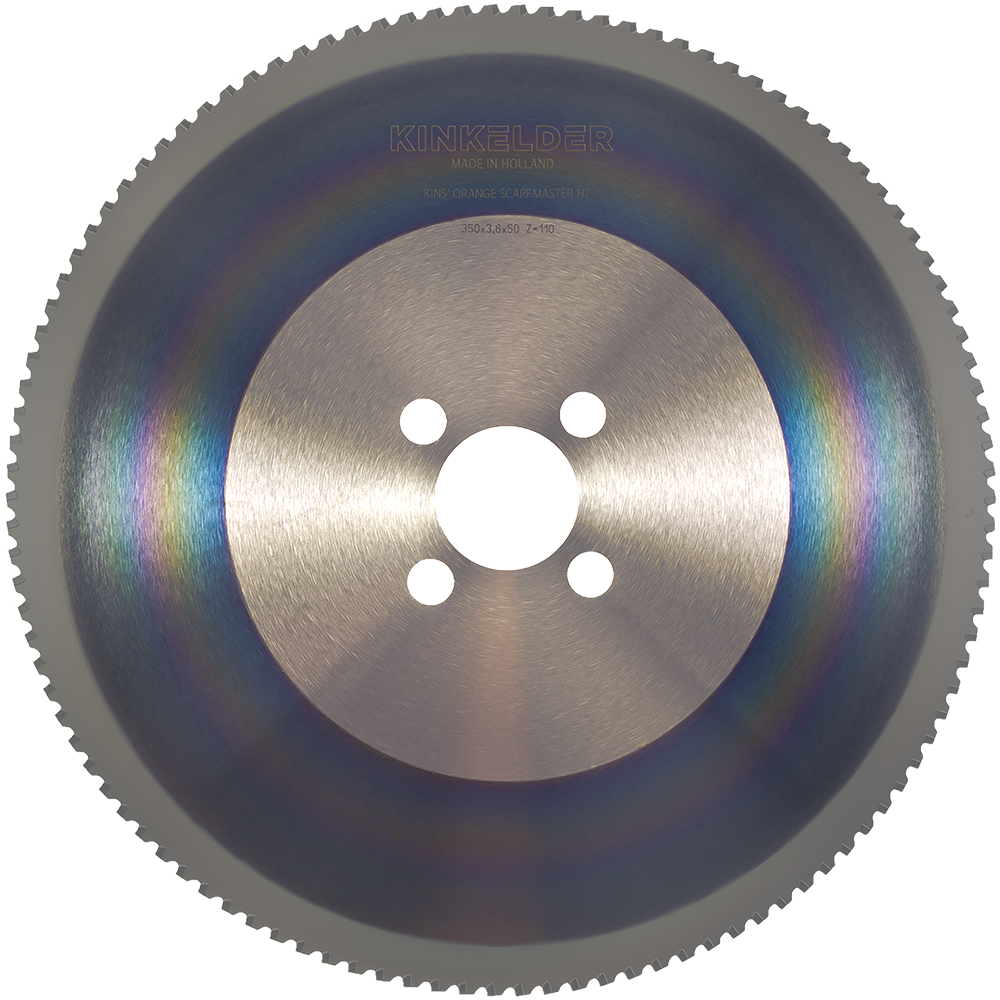

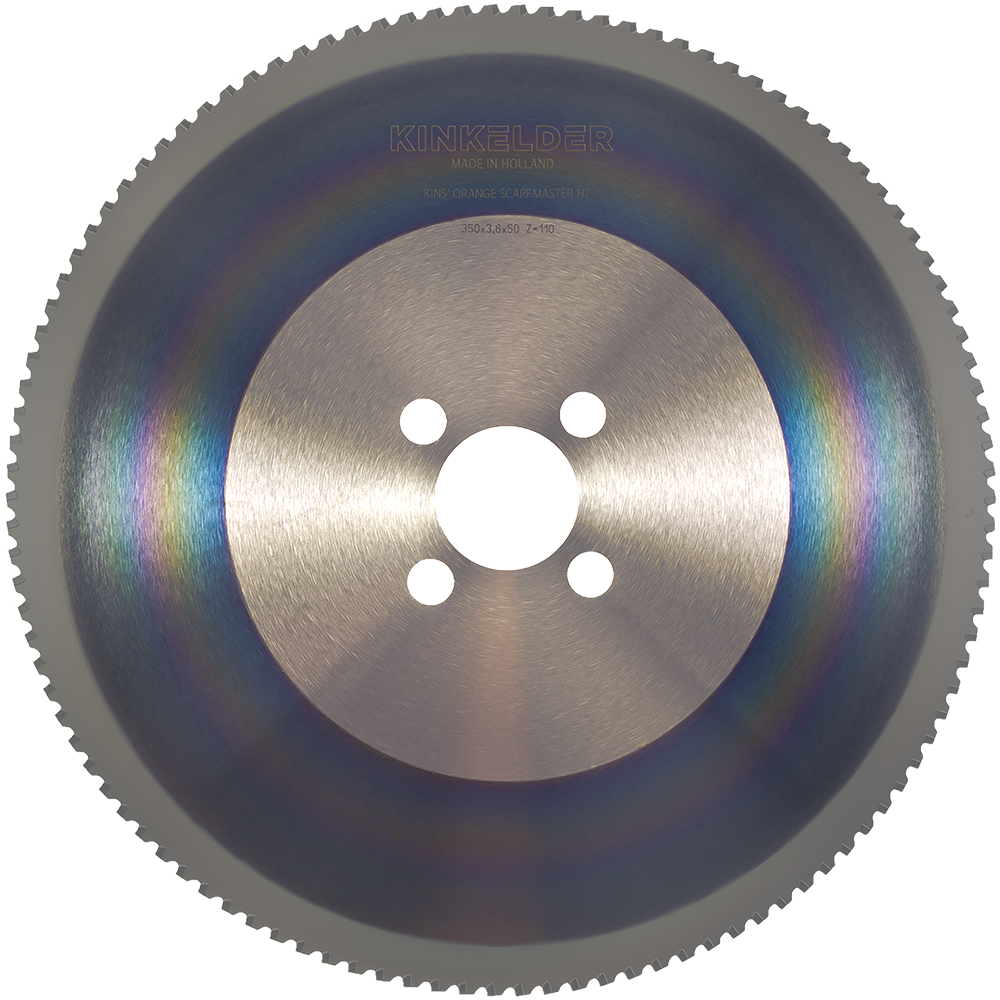

KINS' ORANGE ScarfMaster HT

Single and Twin cut-off with weld bead

KINS’ ORANGE ScarfMaster HT saw blade has been engineered for flying cut-off applications dealing with heavy inside scarf (non-orbital cut-off), offering precision and durability. With its unique tooth geometry, highly shock-resistant carbide tips and special PVD coating, this saw blade is designed for excellence. Where standard blades fail, KINS’ ORANGE ScarfMaster HT is the best fitting blade.

-

Low/Med. Tensile

-

High Tensile

-

Scarf

-

Blade Life