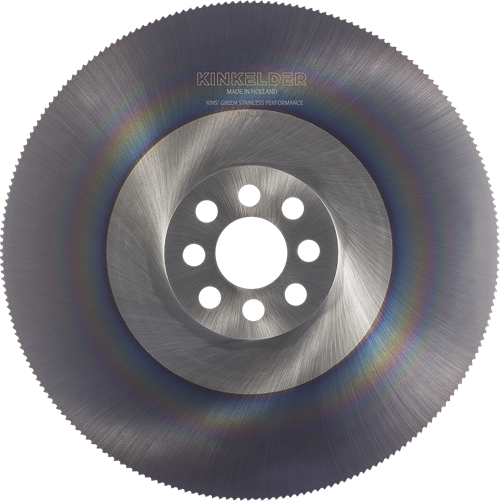

KINS' GREEN Stainless Stabilizer

Crafted to cut thin-walled stainless steel tubes and profiles

The KINS' GREEN Stainless Stabilizer saw blade is equipped with a specialized, thin PVD coating that offers low friction and temperature resistance. Along with a thinned cutting area, these saw blades demonstrate exceptional performance in demanding applications. They guarantee fast and efficient cutting of thin-walled stainless products, minimizing vibration, reducing burrs, diminishing the risk of tube-end deformation, and maintaining high temperature resistance. In challenging cutting conditions, this saw blade ensures optimal performance.

-

Stainless Steel

-

Cutting Speed

-

Blade Life

-

Tube

-

Thin Tube